Injection molding machine for fruit frame

The rod is treated with hard chrome plating on the surface, which is resistant to wear and corrosion.

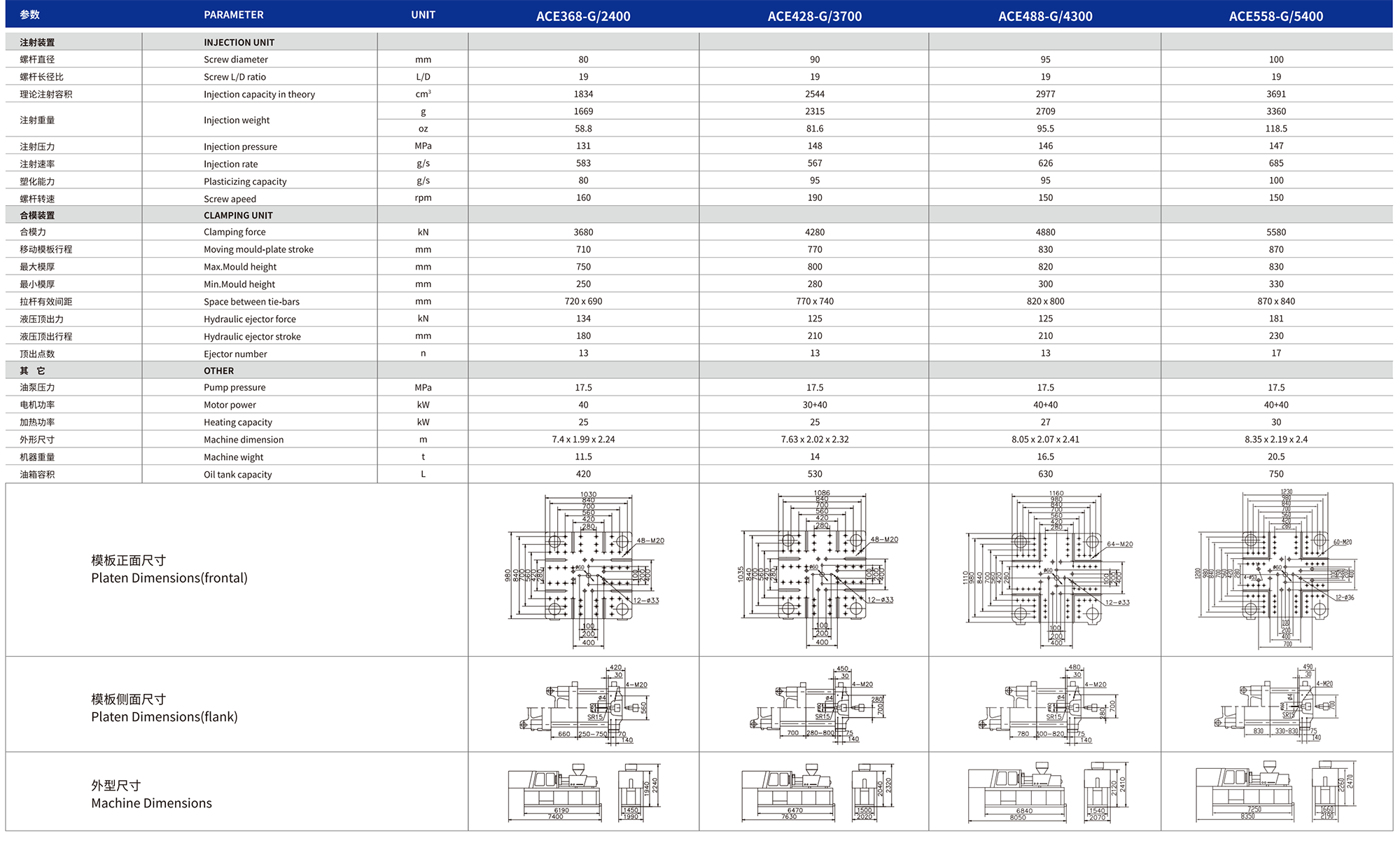

The second plate foot has an adjustable diagonal block structure, which is convenient to adjust after wear, thus extending the service life of the machine.

Automatic centralized lubrication is convenient for machine maintenance.

Adopting synchronous gear adjusting mode, automatic adjusting mode can be realized.

Clamping position ruler connected to the thrust seat, more convenient to adjust the mold protection position.

The optimized design of the machine connecting rod mechanism, the opening and closing die is smooth and fast, and the life is long.

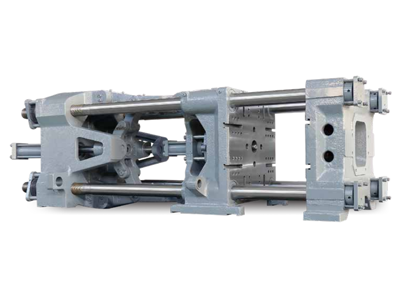

Double injection transfer cylinder, improve injection stability.

Double parallel linear guide rail, improve injection stability and response speed.

High-speed hydraulic motor.

Closed circuit control of injection and holding pressure, precise control of back pressure.

Screw cylinder on the disassembly structure, easy to replace.

High-strength mechanical structure design to ensure lasting precision.

Low speed high torque hydraulic motor drive screw rotation, excellent plasticizing performance.

The optimized design of the screw has wide applicability of raw materials.

The oil circuit system design of the large flow cartridge valve not only ensures the requirements of fast system response and small impact, but also reduces the pressure loss of the oil circuit.

Spiral flow cooler, high heat transfer efficiency, small pressure loss, to ensure the stable operation of the hydraulic system, improve the repeatability and product pass rate.

Low speed and high torque hydraulic motor drives the screw to meet the plasticizing requirements of various raw materials.